Vibrosoiler Mid-Row Results

Why use the Mid Row Vibrosoiler?

With the reduced availability of water resources and limited irrigation available to growers today, the Mid Row Vibrosoiler can successfully act as a ”Water Harvester” opening the soil up and increasing water and nutrient uptake in the root zone where it is needed most.

This is due to the unique vibrating action of the Vibrosoiler which allows break out from the mid row wheel tracks into the uncompacted under vine area without excessive root pruning. This would not be possible with a standard ripper.

Ag Soilworks has been researching and developing the Mid Row Vibrosoiler over 10 years in consultation with leading soil scientists, including Dr Alf Cass, PhD (pictured above) who is one of the worlds leading soil scientists consulting in the US, France, Spain, South Africa and Australia.

What’s the difference?

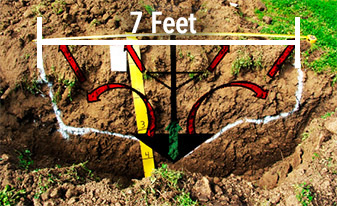

The Vibrosoiler® provides 4 plus times soil breakout from that of a standard ripper with minimal root pruning and lateral breakout to within 6 - 8” of the vine. This removes tractor compaction and the plow pan and increases water and nutrient penetration into the soil profile.

Poor breakout with limited benefit. Requires ripping very close to vine.

The diagram above shows the soil dynamics of the Vibrosoiler® Vibrating ripper. The black downward arrow shows the vibrating direction of the ripper and the red arrows indicate the direction of soil movement. In comparison, the diagram above left shows the lack of soil movement with a wingless conventional shank ripper. ILLUSTRATIONS COURTESY OF DR ALF CASS, SOIL SCIENTIST, PhD

What is Mid Row Ripping?

Mid row ripping is often misunderstood as excess root pruning will set vines back especially in heavy clay soils, we have learnt this the hard way. The Vibrosoiler vibrating wing ripper was designed to produce greater lateral breakout allowing the ripper tine to be further from the vines to loosen the soil from the vine row through the wheel tracks into the uncompacted zone. This is done without excessive root pruning.

Vineyard Compaction

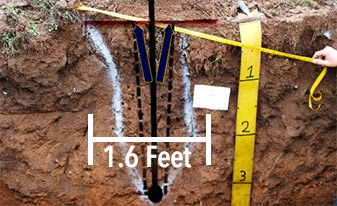

Most vineyard compaction occurs between 200 and 400mm, it is important to rip down to 450mm to 550mm placing the winged keel below the compacted zone. As it lifts it delves up the compaction pan allowing top soil and organic matter to fall into the rip zone, the organic matter retains soil porosity.

Our Approach

In practice, our approach is to mid row rip alternate rows, alternate years with the ripper 20 – 28” from the vine depending on soil type and breakout to loosen the soil into the uncompacted zone in the centre of the planted row.

Root Pruning

For a standard ripper to break into the uncompacted root zone the ripper has to be very close (8-12”) from the vine. This causes excessive root pruning which sets back the vines.

Our units have adjustable row width and wing sizes to fine tune the soil breakout in the vineyard with the soil moisture on that day. On site we first adjust the ripper width to achieve the breakout desired, do half a row and check root pruning, then bring the tines in or out depending on the root growth.

Mk III Unit Features

Adjustable Tines

The MK III Vibrosoiler is adjustable for row widths and is adaptable to suit different soil conditions with different wing options, up to 12” width per keel and shin guard options for sandy and hard soil conditions. Spacing of the tines and adjustment to the soil conditions is critical. In a commercial vineyard (yield of 4T per acre plus) we produce soil break out to within 6 – 8inches of the vine stump removing the compaction zone we then adjust the tine spacing to minimize root pruning to a maximum root size of up to 15mm – 20mm or size of little finger. In high end vineyards, root ripping is limited to about the thickness of a pencil.

Tine Movement

The heaving effect of the Vibrosoiler winged keel produces 4 times the worked soil volume of a standard ripper allowing ripping into the root zone with minimal root pruning not setting vines back.

Ripper Shape

We have flow tested the ripper shape and angle to give tremendous traction by sucking the back of the tractor down and the angles employed minimized the smearing and compaction under the ripper point produced by standard ripping.

Schmeiser Ring Rollers

The unit is fitted with Schmeiser ring rollers (imported from USA) with excellent clod busting abilities leaving a clean finish.