Orchard Development

The success of establishing an orchard, olive grove,

and other permanent crops in a commercial venture

relies on the basic steps of understanding the soils

and how to treat them before planting.

Ag Soilworks Row alignment using GPS-RTK AutoSteer Cat Challengers with sub 1in accuracy ripping on the future tree row creates large, uniform loosend soil under the irrigation, concentrating organic carbon and amendments in the planting line and blending down 3 to 4ft. Our Ripping System is ready to plant once complete. No need for re-leveling, scraping, or building tree mounds, simply mark tree placement and plant. Offering a wide variety of mound widths and heights, AG Soilworks will surely produce the desired finish with the Patented GPS Ripping System.

Two to three passes. 13ft x 1.4ft untilizing 8" of top soil.

One to two passes. 6.5ft x 1.1ft utilizing 6" of top soil.

Vibrosoiler promotes establishment and uniformity and health.

AG SOILWORKS VIBROSOILER – SUPERIOR RIPPING RESULTS

AG SOILWORKS VIBROSOILER – SUPERIOR RIPPING RESULTS

As soil flows over the vibrating wings it crumbles as it falls. The movement promotes the blending of compost and ameliorants down into the profile. Two passes produce a consistent tilth with ameliorants blended into the profile 3ft - 4ft Soil compaction is reduced significantly using the Caterpillar Challenger Track Layer (7psi).

Olives

The success of establishing olives and other crops in a commercial venture relies on the basic steps of understanding the soils and how to treat them before planting.

WHY IS AG SOILWORKS SYSTEM SUPERIOR?

SOILWORKS VIBROSOILER - EXCELLENT RIPPING RESULTS

Soil compaction reduced significantly producing good consisten planting bed. As soil flows over the vibrating wing it crumbles as it falls. The movement promotes the blending of compost and ameliorants down into the profile . Two passes produce a consistent tilth with ameliorants blended into the profile to 3ft.

First Pass - ripping to depth, delving an open trench

- Addition of amendments and organic matter directly into trench with spreader • straddling the row

Second Pass - Ripping & Bedding

- Deep rip, blend amendments to depth, pull ready to plant berm

Incorporation of organic matter 2ft deep

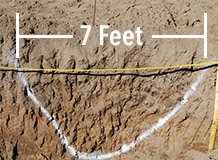

4ft deep, 7ft breakout – Precision ripped on planting line, all plants in worked soil.

SOILWORKS ADVANTAGE OVER CONVENTIONAL RIPPING METHODS

- Vibrosoiler ripping produces 4 - 5 times soil breakout volume in a single pass than a traditional slip plow

- Produces soil consistency and a uniform ‘ready to plant’ bed

- Increased root development and larger root zone

- 2 Pass System - no further cultivation required

SLIP PLOW PITFALLS

- Soil profile recompacts and mixes subsoil into top soil

- Soil is unworked resulting in poor root development

- Planting bed lacks uniformity

- Extra passes required before planting

Traditional Slip Plow Ripping - leaves an uneven ripping result with compacted soil zones and a lumpy finish

The images below show traditional slip plow ripping in comparison to the Ag Soilworks Vibrosoiler ripper above. As shown below left the bulldozer drives over the ripped row recompacting the ripping line in the process. The center image shows the ripping shape produced by the slip plow which is uneven with only every second 20” being ripped leaving 20” unworked. Within the soil pit analysis we used a penetrometer to determine the quality of ripping and found the bulldozer showed a limited effect in reducing soil compaction with variable results leaving the soil consistency uneven with compacted zones and lumpy boulders throughout the soil profile. There was no blending of broadcast compost and ameliorants into zone.

Traditional Ripping

Traditional RippingD8R 4ft centers, drives in ripped row and compacts ripping line in process

Poor root development, every 2nd planting is in the 'unripped' zone - 20" ripped, 20" unworked

Poor drought tolerance. Plant planted off rip line shallow rooted, roots chasing rip line

For more info see "Gonzales Field Day".

Root Zone Management Plant Ready System

2 PASS SYSTEM - 4' »

3 PASS SYSTEM - 4'+ »

4 PASS SYSTEM - 5' »