Vineyard Development

AG SOILWORKS tailors precision ripping

and development techniques to specific

soils using the Patented Vibrosoiler ripping

process, deep compost amendment placement,

discing, and mounding in a single GPS-RTK AutoSteer pass.

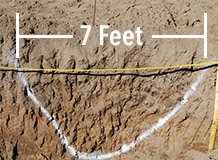

There is no surveying required, pegging of rows for QA purposes only. There is minimal soil re-compaction by the Caterpillar Challenger track units (7psi) & the D10's Vibrosoiler for maximum breakouts to 6ft, which enables better root development and increased crop yield. AG Soilworks Vibrosoiler achieves 4-times the worked soil volume of a standard ripper with a soft U-shaped rip line. Utilizing the unique AG Soilworks Development Mounder fitted to the rear of the Vibrosoiler unit; ripping, bedding, mounding, and incorporation of organic compost is accomplished in the final pass of our Development System. AG Soilworks Development Technology offers a range of solutions to maximize crop yield potential using 1 to 3 winged parabolic rippers up to depths of 5ft.

AG SOILWORKS current practice is to 1st Rip 3ft and Delve rows to 18”, 2nd add organic matter, 3rd rip to max depth, mix, and mound in a single pass with the Vibrosoiler and Mounder. With this approach we can successful incorporate organic matter down to depth and mound as desired mixing two inches of top soil into the root zone area, making use of organic carbon and humus in the soil. This increases available water holding capacity, the buffering chemical (AWHC), and promoting uniformity through the soil profile.

WHY IS AG SOILWORKS SYSTEM SUPERIOR?

SOILWORKS VIBROSOILER - EXCELLENT RIPPING RESULTS

Soil compaction reduced significantly producing good consisten planting bed. As soil flows over the vibrating wing it crumbles as it falls. The movement promotes the blending of compost and ameliorants down into the profile . Two passes produce a consistent tilth with ameliorants blended into the profile to 3ft.

First Pass - ripping to depth, delving an open trench

- Addition of amendments and organic matter directly into trench with spreader • straddling the row

Second Pass - Ripping & Bedding

- Deep rip, blend amendments to depth, pull ready to plant berm

Incorporation of organic matter 2ft deep

4ft deep, 7ft breakout – Precision ripped on planting line, all plants in worked soil.

SOILWORKS ADVANTAGE OVER CONVENTIONAL RIPPING METHODS

- Vibrosoiler ripping produces 4 - 5 times soil breakout volume in a single pass than a traditional slip plow

- Produces soil consistency and a uniform ‘ready to plant’ bed

- Increased root development and larger root zone

- 2 Pass System - no further cultivation required

SLIP PLOW PITFALLS

- Soil profile recompacts and mixes subsoil into top soil

- Soil is unworked resulting in poor root development

- Planting bed lacks uniformity

- Extra passes required before planting

Traditional Slip Plow Ripping - leaves an uneven ripping result with compacted soil zones and a lumpy finish

The images below show traditional slip plow ripping in comparison to the Ag Soilworks Vibrosoiler ripper above. As shown below left the bulldozer drives over the ripped row recompacting the ripping line in the process. The center image shows the ripping shape produced by the slip plow which is uneven with only every second 20” being ripped leaving 20” unworked. Within the soil pit analysis we used a penetrometer to determine the quality of ripping and found the bulldozer showed a limited effect in reducing soil compaction with variable results leaving the soil consistency uneven with compacted zones and lumpy boulders throughout the soil profile. There was no blending of broadcast compost and ameliorants into zone.

Traditional Ripping

Traditional RippingD8R 4ft centers, drives in ripped row and compacts ripping line in process

Poor root development, every 2nd planting is in the 'unripped' zone - 20" ripped, 20" unworked

Poor drought tolerance. Plant planted off rip line shallow rooted, roots chasing rip line

For more info see "Gonzales Field Day".

Root Zone Management Plant Ready System

2 PASS SYSTEM - 4' »

3 PASS SYSTEM - 4'+ »

4 PASS SYSTEM - 5' »